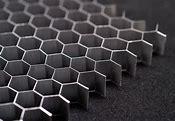

Definition

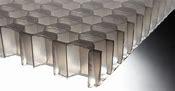

Lightweight, hexagonal-shaped structures used in sandwich panels.

Materials

Can be made from aluminum, Nomex, Kevlar, or thermoplastics.

Advantages

- High strength-to-weight ratio.

- Excellent energy absorption.

- Good thermal insulation.

Applications

Used in aircraft floors, doors, and control surfaces.

Types of Honeycombs for Aircraft

1. Aluminum Honeycomb

Characteristics

High strength, lightweight, good corrosion resistance.

Applications

Aircraft flooring, panels, and control surfaces.

2. Nomex Honeycomb

Characteristics

Lightweight, good thermal and fire resistance, made from aramid paper.

Applications

Interior panels, flooring, and secondary structures.

3. Kevlar Honeycomb

Characteristics

High strength, lightweight, excellent impact resistance.

Applications

Radomes, fairings, and other components requiring high impact resistance.

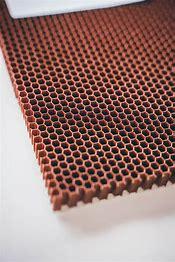

4. Thermoplastic Honeycom

Characteristics

Lightweight, good impact resistance, and moisture resistance.

Applications

Aircraft interiors and partitions.

5. Fiberglass Honeycomb

Characteristics

Good thermal and electrical insulation, lightweight.

Applications

Aircraft interiors, electrical enclosures.

Prepreg

Definition

Fibers pre-impregnated with resin, ready for use.

Components

- Fibers: Carbon, glass, aramid.

- Resin: Epoxy, phenolic.

Advantages

- Consistent resin distribution.

- Reduced voids.

- Improved properties.

Storage

Often refrigerated.

Usage

High-performance aircraft structures.